The workshop production schedule is used to plan production orders (POs), optimise the use of machines, schedule the work of workers and make better use of all the equipment in the workshop. In a context where deadlines are tight and costs needs to be controlled, having the right software and efficient methods has become essential.

What is a workshop production schedule?

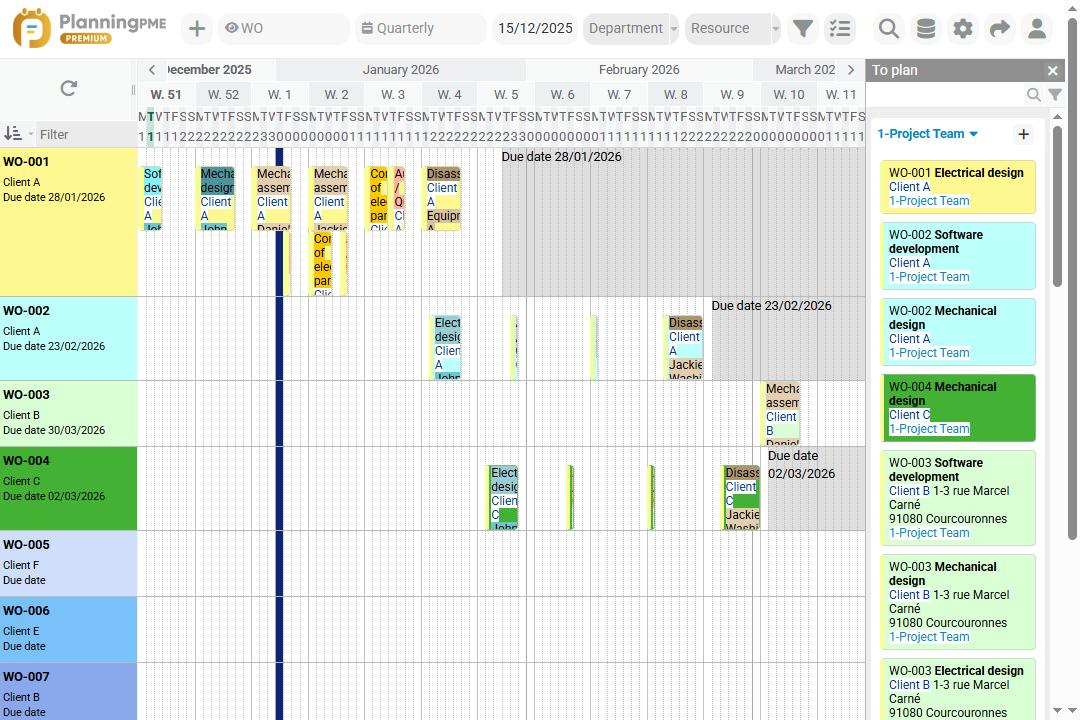

A workshop schedule enables you to sequence your production orders (POs) using workshop resources (machines, workstations, teams), taking into account capacity, unavailability, priorities and lead times. With PlanningPME, you can visually monitor your workload, anticipate bottlenecks and secure your deliveries. The solution is used in manufacturing and similar industrial environments.

- Machines and workstations : availability, maintenance, set-up times.

- Workers and teams : schedules, absences, skills.

- Specific equipment : tools, vehicles, shared facilities.

- Workload : optimal distribution of the workload according to the schedules and availability of human and material resources.

A workshop schedule enables you to deliver on time, while controlling overall costs and optimising resource utilisation.

What are the advantages of workshop production scheduling software?

A workshop schedule helps to reduce delays, control costs and improve overall productivity. While it's possible to get started with tools like Excel, the limitations quickly become apparent: lack of visibility, manual errors, difficulties in managing contingencies.

Here are some of the benefits and key features of workshop planning software such as PlanningPME :

Intuitive, visual planning

Team management

Smooth communication

Multiple views and filters

PO planning

Just-in-time production and continuity

Accessibility

Capacities, time off and machine breakdowns

Plan your workshop production activities

Create your workshop schedule in 7 steps

To successfully set up an efficient workshop production schedule, follow these 7 key steps that will guide you step by step, from identifying resources to adjusting them in real time.

- Identify workshop resources : List the machines, workstations, operators, teams and equipment needed for production.

- Define workshop production orders and operations : Structure your production orders by integrating the tasks specific to your activity, the planned delivery dates and the associated customers.

- Estimate time and constraints : Evaluate the duration of each operation, taking into account preparation and maintenance times and capacity and skill constraints.

- Schedule production timeline : Sequence the POs on available resources using the different views of the visual scheduling tool (team view, PO view, customer view, project view) to balance workload and capacity.

- Distribute and share the workshop schedule : Make the schedule available to teams (web, mobile, workshop screen) so that everyone has the same up-to-date information.

- Monitor progress and make adjustments in real time : Monitor the execution of POs, identify delays or emergencies, then reorganise the workload immediately.

- Download a free production schedule template : Get started quickly with a ready-to-use template for structuring and optimising your workshop schedule.

By creating your production schedule with the software, you can transform your workshop: more visibility, fewer delays and customers delivered on time.

Create your production schedule

Comparison of workshop scheduling solutions

| Solution | Advantages | Disadvantages |

|---|---|---|

| Excel / Spreadsheet | Free or already installed Flexible and customisable Simple for small volumes |

High risk of manual errors Difficult to share and maintain Limited as the workshop grows |

| PlanningPME | Machines, teams and POs in a single tool Clear interface and multiple views Alerts and contingency management |

Cost of licence or subscription Initial settings for advanced functions |

| Other software | Wide choice of specialist tools Can integrate ERP/ stock/ purchasing Adaptable to specific needs |

Often at high costs Complexity and extensive training May be too complex for small companies |

Discover our PlanningPME customers' success stories

Our first needs were to have a planning tool that was easily integrated into our business processes, flexible, and able to take pride of place in the daily management of our activities and resources. Using PlanningPME gave us complete visibility to coordinate our multifunctional, always-on-the-move work teams. In addition, its integration within our business systems has simplified our project management activities, allowing us to cover the process from the creation of a new job to its reporting. In addition, the monitoring of the order allows us to have sensitivity to any deviations, both before, after and during.

Somtec CH

Disenos NT

FAQ

Large-scale production planning is used to anticipate medium/ long-term requirements (volumes, overall capacity). The workshop production planner works on a daily basis to sequence POs, manage urgent situations and deliver on time.

The interface is designed to be intuitive: most of our customers are operational within a day.

A spreadsheet may be enough for small volumes of data, but it quickly becomes limited: no real-time updates, frequent errors and complicated sharing. As soon as the workshop grows or several resources need to be managed in parallel, dedicated software such as PlanningPME becomes essential.

The most commonly used are on-time delivery (OTD) rate, rate of return (overall equipment effectiveness/ overall operations effectiveness), work in progress (WIP), average delay rate and load/ capacity comparison. These indicators help identify bottlenecks and improve overall workshop performance.

Yes, solutions such as PlanningPME offer a free trial enabling you to test the planning of machines, teams and production orders before making any commitment. It's a quick way to check whether the tool meets your needs.

30-day free trial to boost your schedule management

Request a demo Free trial